Many manufacturers have chosen to use polypropylene to make their interlocking floor tiles. For some applications it is the most suitable material. Here we explain when you should select PVC and why.

-

Flame retardance

Neither PVC nor polypropylene are naturally flame retardant but it is much easier and cheaper to incorporate a flame retardant additive in to PVC.

Ecotile does not support combustion and achieves Class 1 spread of flame when tested to BS 476: Part 7 / European Classification: BFL. In other words, it will not support a flame and does not give off toxic fumes if it’s in a fire. It can be prohibitive expensive to get polypropylene to the same standard so if this is important to you, make sure you check with the manufacturer and ask to see their test certificate. Here you can find our fire test certificate.

-

Load bearing

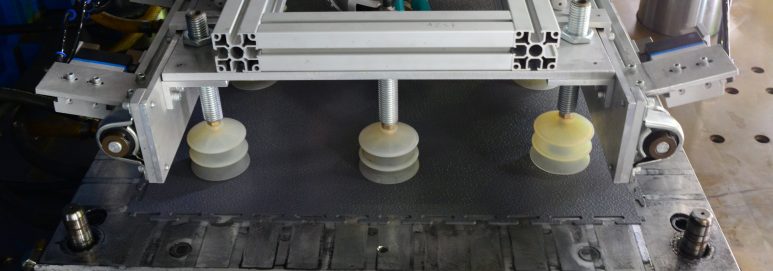

You may have noticed that PVC tiles tend to be solid where polypropylene tiles usually have a grid structure. This is due to the nature of each material dictating the way it can be moulded. PVC needs fewer flow lines to achieve dimensional stability and prefers a solid structure. As a result it is able to support heavier loads and offers better impact resistance. Polypropylene can be brittle and snap under stress. You will want to consider this if you will be using forklifts or heavily loaded pallet trucks on the tiles.

-

Flexibility of PVC

Another useful property of PVC that contributes to its suitability for bearing heavy loads is its flexibility. The rigid structure of polypropylene tiles means the substrate you lay them on needs to be flat. However, PVC tiles will follow the contours of the floor and cope with unevenness. If your existing floor is damaged or over several levels you’ll find PVC tiles are more forgiving and easier to install.

-

Anti-slip

There’s a common misconception that because polypropylene tiles often have drainage holes in them they offer a higher level of anti-slip protection. Actually the holes are usually there because it’s easier to manufacture polyprop tiles that way or because it’s cheaper. You use a lot less material! If you stand on a PVC tile and scuff your shoe back and forth and try the same thing with a polyprop tile you’ll find there’s a lot more resistance and friction from PVC. All of our tiles achieve an R10 slip rating.

-

Sound insulation

This is a very underrated advantage of PVC. No one buys Ecotile specifically to reduce noise in their factory or warehouse but everyone comments on what a difference it has made afterwards. The combination of the solid structure lying flat on the floor with the dense nature of the material is great for sound insulation. Ecotile can produce a reduction of up to 46 decibels, which in a cavernous warehouse or noisy production area is a huge improvement. Speaking of which, Ecotile provides a warm and comfortable surface to work on too so staff will feel a noticeable difference at the end of the day.

Check out our testimonials and case studies for confirmation.

CEO and founder James Gedye has established Ecotile as the leading provider of interlocking floor tiles to the UK and around the world. Founded in 1996 from his bedroom turned office, James has built Ecotile into a multi-million-pound business, with sustainability still at the heart of his vision.

Based in Luton, Bedfordshire, Ecotile remains a privately owned UK manufacturing company, precision engineering all products in a purpose-built ISO accredited factory.

Leading the company to 2 prestigious Queens Awards in 2017 for Enterprise for Innovation and International Trade, these accolades underline James’ desire to create the highest quality products and fly the flag for British manufacturing. Working directly with leading businesses for over 25 years, James’ Ecotile brand has become synonymous with trust.

Used by 1000s of leading businesses, trusted by the MoD and specified by contractors, Ecotile floor tiles can be found across the world.

Connect or follow James on LinkedIn…