- BS EN 61340-5-1 Edition 2 2016-05

- IEC 61340-5-1 Edition 2 2016-05

- ANSI/ESD S20.20-2014

- Click For Full Details

- Motorola R56

- IBM Data Center Recommendations

- BS EN 1081:2018 + A1:2020

ESD Protective Flooring

Installed Quickly Without Disruption or Downtime

Ecotile manufacture high performance static-dissipative floor tiles that protect microelectronics, static-sensitive devices and explosives from damage caused by static discharge.

Performing two core functions, our ESD interlocking floor tiles can be installed quickly and used as the cornerstone of your static-control program:

- Provides a traceable path to ground (> 3.4 x 104Ω and ≤ 5.0 x 106Ω)

- Prevents static generation (< 100 volts)

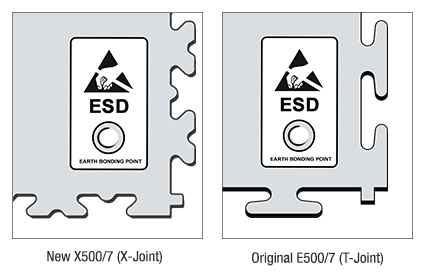

Ecotile ESD tiles are available in two different interlocking joint designs. Our X500/7 X-Joint Tile is the latest addition to our range, with our original E500/7 ESD tile featuring a T-Joint connection.

Both versions are 7mm thick and available in dark grey. Please enquire for more information.

Please note that the joints of both tiles do not fit together with each other, so if you are extending an area of tiles, you’ll need to install the same joint style.

The First Line of Defence Against Static

Whether you are looking to replace a failed/worn floor or create a new ESD protected zone, Ecotile can be integrated into your static-controlled area without hassle.

- Lifetime guarantee of ESD performance

- No disruption or downtime during installation

- Can be lifted quickly (ideal for leased/temporary spaces)

- Completely reusable, so you’ll never lose your initial investment

- No adhesives, special floor prep or moisture protection required

- Installable over almost any subfloor

- End-to-end solution (including installation, testing and certification)

- Resistant to chemical spills

- Anti-slip and anti-fatigue properties

- Suitable for use in Class 7 & 8 cleanrooms

- 10 year warranty

Ecotile have over 25 years of experience manufacturing, specifying, and installing ESD flooring for use in electronics manufacturing facilities, circuit assembly/handling areas, cleanrooms, laboratories, data centres and explosive ammunitions facilities.

Installation Service

Our professional installation team have decades of experience installing and testing Ecotile ESD floors.

Modular Solution

Loose lay with a mallet, no adhesives required. Add, remove or replace individual tiles when you need to.

Logo Tiles Available

Add safety markings with our ESD logo tiles. Clearly label areas that are protected from static discharge.

Let's Get Started

How Ecotile Provides a Dependable Path to Ground

Stainless-steel microfibers are added throughout the inner structure of each PVC tile. These microfibres act like conductive veins that draw electric current from the surface of the floor through its entire thickness.

No wear layer is required. Ecotile ESD tiles do not loose their ESD properties over time.

A tile with a grounding stud is installed every 60m2 and is connected to an earthing point, allowing static to complete its circuit and flow safely to ground.

Ecotile ESD flooring is installed over a grid of conductive tape laid on the subfloor which unifies conductivity through contiguously installed tiles.

Post Installation Testing & Certification

It is critical that your floor meets industry specific standards and falls within the agreed electrical resistance range after it has been installed.

Our tiles have been tested independently against EN 14041:2018

Ecotile Flooring can test your new floor against the standard of your application and provide you with a written certification of compliance.

An ongoing test schedule can also be implemented. As per BS EN 61340 Guidebook recommendations, Ecotile can test your floor annually or as frequently as you require.

Full support and recommendations for after-care are provided, ensuring a suitable floor cleaning routine is implemented.

What to Know Before Specifying ESD Flooring

Any ESD floor can fail if it’s specified for an incompatible space or does not meet the proper industry-specific ESD standards.

To avoid costly mistakes, ensure you familiarise yourself with the basics of ESD flooring.

- ESD floors are part of a system and should be used with other ESD measures i.e. footwear

- Standards vary by industry. Standards for electronics manufacturing and handling differ from those governing telecom, PSAPs, FAA flight towers, and other end-user spaces.

Anti-static flooring is not the proper term to use for an ESD floor

Anti-static flooring simply controls charge generation and static build up.

These types of floors will not safely eliminate a static charge before it randomly discharge.

ESD flooring systems are classified as static conductive (more conductive) or static dissipative (not as conductive, but will dissipate charges in a controlled fashion).

Ecotile specialise in static-dissapative flooring.

Want to learn more about the basics of ESD flooring?

Paxton Access Control

"Ecotile was the most practical solution as we didn’t need to stop production for a moment and we were amazed how quickly it was completed."

West Control Solutions

"It wasn’t viable for us to shut down operations to install an ESD floor so the fact that Ecotile could go straight over the top whilst we continued to work was a huge advantage"

Ecotile ESD Flooring has been tested to and meets the following international standards:

BS EN 61340-5-1 Edition 2 2016-05 – Electrostatics. Protection of electronic devices from electrostatic phenomena.

IEC 61340-5-1 Edition 2 2016-05 – Electrostatics. Protection of electronic devices from electrostatic phenomena

Human Body Model (HBM) Testing & EN / IEC 61000-4-2 Edition 2 2016-05 2008.

ANSI/ESD S20.20-2014 & ESD STM97.1-2015

BS EN 1081:2018+A1:2020 – Resilient floor coverings. Determination of the electrical resistance

MOD DSA03. OME Part2 (JSP482) & US MIL-STD-1686

Finish: Smooth

Material: PVC

Resistance: > 3.4 x 104Ω and ≤ 5.0 x 106Ω

Body Voltage: < 100 volts

Dimensions: 497mm x 497mm

Thickness: 7mm

Weight: 8.40kgs/m²

Slip Resistance: R10

Fire Performance: Bfl-S1

Chemical Resistance: Good EN 13529

Note: All figures quoted relate to laboratory testing in accordance with LVS EN IEC 61340-4-5:2018

Accreditations:

Specification

Finish: Smooth

Available in X500/7 or E500/7

Material: PVC

Resistance: > 3.4 x 104Ω and ≤ 5.0 x 106Ω

Body Voltage: < 100 volts

Dimensions: 497mm x 497mm

Thickness: 7mm

Weight: 8.40kgs/m²

Slip Resistance: R10

Fire Performance: Bfl-S1

Chemical Resistance: Good EN 13529

Let's Get Started

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |